Technology and processes

Additive manufacturing uses a wide range of technologies and processes, including photopolymerization, extrusion, material spraying, powder fusion, direct energy deposition and sheet lamination.

Process and Material Panorama

Source: Diagram from 3D Hubs. Additive Manufacturing Poster, 2019, enhanced with CSAM in the “Direct Energy Deposition” section.

Benefits of AM

Additive manufacturing offers several advantages. It allows for the manufacturing of parts using a wide range of materials, including polymers, metals (aluminum, cobalt, chromium, nickel, titanium), ceramics, composites, and even organic materials (wood, waxes, foodstuffs, biological tissue), with higher complexity levels and greater lightness than conventional machining and moulding processes.

- Freedom of form: Industrial draftspersons and designers can produce parts that were previously impossible or difficult to produce through conventional manufacturing methods (machining, moulding) while reducing production costs;

- Cost: The manufacturing complexity does not increase the cost when the part has been designed according to a set of rules. AM parts also require a lesser amount of materials than those manufactured through other processes;

- Innovation: AM opens the door to several new advanced materials to meet an increasing number of manufacturing challenges;

- Time: AM was first used for prototyping to obtain a proof of concept quickly. Today, more and more technologies are able to create finished products, thus reducing manufacturing times to a minimum;

- Logistics: Mechanical assemblies can be redesigned and replaced by a single 3D printed part, which can generate savings by reducing the number of orders, or by simplifying inventory and logistics;

- Sustainable development: AM allows for on-demand and local production, thus reducing the environmental impact when transporting goods. It also reduces the raw materials needed while paving the way to near-infinite recycling possibilities.

The am Value Chain

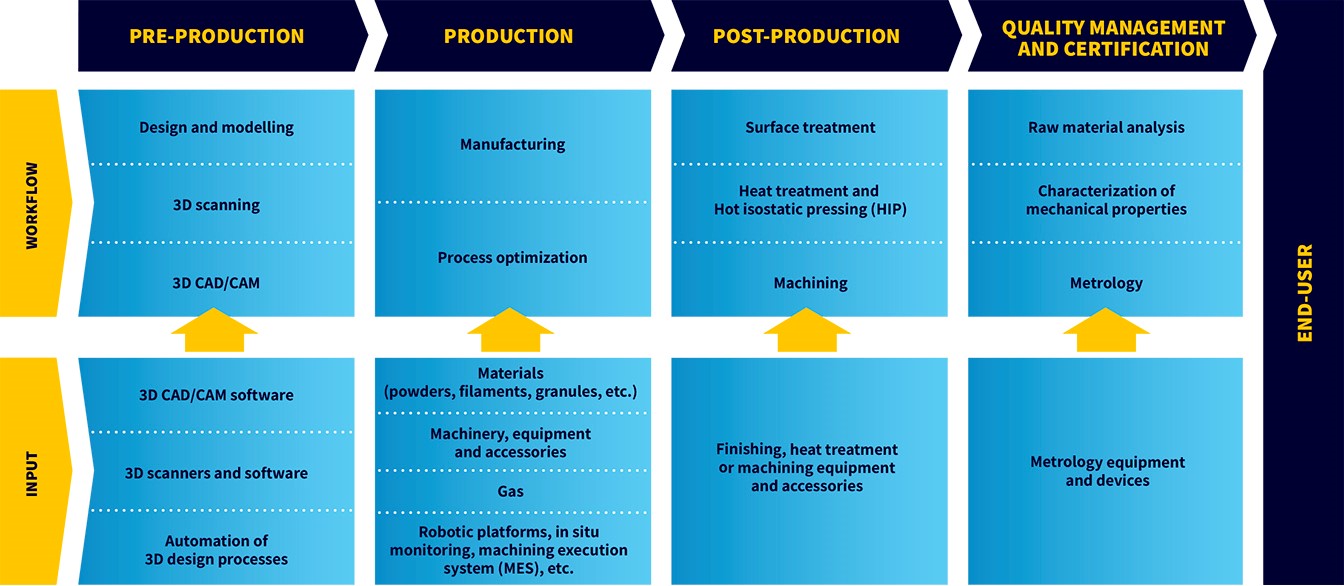

Stakeholders in Quebec’s AM ecosystem cover the entire value chain, from pre-production to end users, from production to quality management and certification.

The following diagram summarizes the elements that belong to Quebec’s ecosystem value chain.